|

Positive Thermal CTP Plate

Extraordinary Plate Developing Tolerance - User Friendly and Dealer Friendly

Ronsein thermal CTP plate has wide plate developing tolerance. So it is suitable for most developer and

the different concentration. So it is very good for the user and

dealer to do the plate testing or plate using.

High Resolution

Ronsein's unique ingredients, together with the optimally

distributed formula weight of binding polymers, in the coating of

KTP offer fine dots with sharp edges and reproduce images with rich

tone. The aluminum matrix of compound grain molybdenum structure

technology ensures 1-99% microdot reproduction.

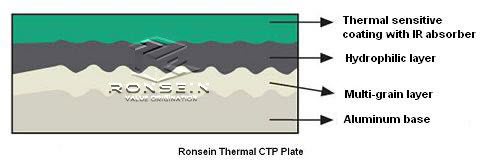

Good Quality of Printing Effect - Excellent Hydrophilicity

Hydrophilic treatment and post anodizing treatment provide excellent

water retaining capability at the non-image area and prevent

scumming.

Long Run Length - Multi-grains Structure

The multi-grains structure of Ronsein CTP plate improves water

retaining capability and keeps ink-water balance optimally.

Working Principle

Marco-molecules are formed by cross-linked micro-molecules during

the oven drying procedure of Ronsein CTP plate production.

(A) Thermal sensitive coating with IR-Absorber;

(B) Hydrophilic layer formed by sealing

treatment;

(C) Electrochemically grained and anodized

aluminum.

Infrared Laser exposures the non-image area.

The IR-Absorber in the thermal sensitive coating converts light to

heat and breaks the cross-linked structure.

The deformation of macro-molecules at the

non-image area makes the coating alkaline soluble (Developer)

Image area remains insoluble to the developer.

|

Technical

Data

|

Brand |

Ronsein-TPP |

|

Label |

Ronsein label, no label or customer label |

|

Gauge

|

0.15 - 0.40 mm

|

|

Spectral Sensitivity

|

830 nm

|

|

Exposure Energy

|

110 - 130 mj/cm2

|

|

Resolution

|

1% - 99% at 250lpi

|

|

FM

Capability

|

20 um

|

|

Run

Length

|

100,000 - 200,000

actual run length may vary according to press, ink and paper

condition.

|

|

Plate Developing Condition

|

Recommend Developer

|

Ronsein developer, Kodak developer, Agfa developer or

Fuji developer

|

|

Protection Gum

|

recommended to use 140G protection gum

|

|

Developing Temperature

|

22 - 24 degree Celsius

|

|

Developing Time

|

25 - 35s

|

|

Plate Baking Condition

|

Replenishment Rate

|

100 ml/sqm

|

|

Baking Preparation

|

applied any suitable plate baking gum

|

|

Baking Temperature

|

stand oven: 220 - 230 degree Celsius for 5 minutes

online oven: 240 degree Celsius for 4 minutes

|

|

Storage Information

|

Run

Length after Baking

|

500,000

|

|

Safe

Light

|

daylight handling

|

|

Shelf Life

|

12

months under recommended storage conditions (10 - 30 degree

Celsius, relative humidity: ≤65%, stacking height ≤ 1.5

meter)

|

|

Package |

0.15mm, 100 sheets per carton

0.30mm, 50 sheets per carton

|

|